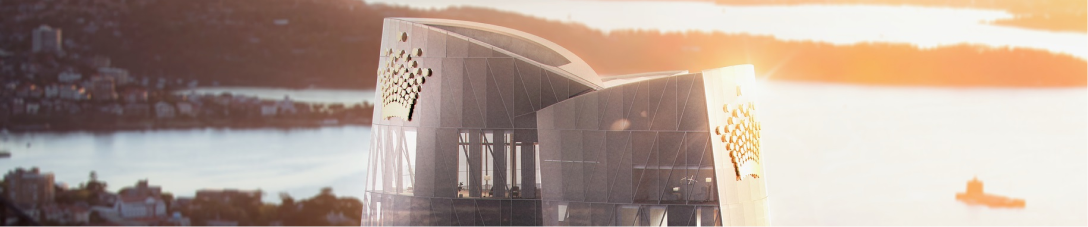

At an amazing 19 meters above ground, the Soffits at Jubilee Place are a truly unique and innovative development delivering architectural excellence and requiring an equally brilliant framing solution from Rondo.

Jubilee Place includes the rejuvenation of the Jubilee Hotel – an iconic building designed by architect Richard Gailey and constructed in 1887. The Jubilee Hotel was among the many designs that collectively set a precedent for the signature style of the historical architectural landscape in Brisbane’s Fortitude Valley, earning its heritage-listed status in 1992.

The strategic location of The Jubilee Hotel presented a development opportunity for JGL properties, who planned to maximise the usability of the site, designing a “workplace of the future”with the assistance of architects Blight Rayner, who understood the heritage nature of the hotel and the presence of the tunnel that runs directly under the hotel.

Blight Rayner’s design incorporates lighter-in-weight materials to ensure that there would be no impact on the tunnel, whilst maintaining functionality for the new developments’ office and retail spaces. With the Clem Jones Tunnel running just 16.3 meters below the new building car park, the total weight of the building was a major factor in ensuring the preservation of the tunnel.

The superstructure of the building was designed with steel to reduce the total weight of the building, which was then clad using Rondo lightweight steel framing. Partnering with Contractor, North Australian Contracting (NAC), to deliver the captivating Soffit Shapes, this project is a perfect example of how Rondo’s Smart-Wall® Prefabricated Framing System offers faster installations on site whilst achieving complex designs.

Jubilee Place was designed as a 15-storey development with open floor plans that part-cantilever over the hotel, leaving the structure of The Jubilee Hotel untouched. The cantilever also acts as a canopy to Jubilee place, creating a public plaza area that links the old world with the new.

The hotel location significantly increased construction difficulties, with the Jubilee Place Soffit extending over the top of the hotel, it created one of the most complex parts of the construction. Furthermore. the Soffit consisted of irregular shapes and with the superstructure itself needing to be concealed, a lightweight prefabricated Steel framed solution was the logical choice. To add further challenges, all this had been constructed some 19m above ground level, with a heritage-listed structure directly below.

When working at height, the first concern is the safety of installers with an increased responsibility to prevent falls. For areas above the Jubilee hotel where the Soffit was a huge 19 meters above ground, a boom lift was used in place of the scissor lift. For a boom lift, the user is required to wear a harness and the platform space is decreased. This increases the complexity of the work, having to take into account working at heights with a limited workspace and weight capacity whilst installing irregularly shaped frames over the top of a heritage building, which is rarely seen.

As North Australian Contracting (NAC) are, experts in installing Rondo prefabricated Steel Stud frames on major projects, they knew that to reduce the time their people spent working at height to improve safety and speed up installation, they would once again need Rondo’s innovative Smart-Wall® Framing System. Rondo worked with NAC on the Soffit designs and then manufactured and assembled the prefabricated frames at our facility located in Yatala, QLD. NAC surveyed the in-situ Structural Steel framing and developed the frames required to align with the structural steel. They also split the prefabricated steel into sections which are made up of different frame sizes that are designed to suit the lifting equipment and transport required.

By working closely with NAC, Rondo was able to take these site measurements and design the Smart-Wall® prefabricated Wall Framing System (64mm 0.75mm BMT System). The designs were coordinated by NAC, confirming each frame meets the plan. Once all components were detailed and approved, Rondo began roll-forming the steel sections on our specialised machines. All Smart-Wall® framing products were roll-formed in Yatala QLD to form the complete system, including Steel Studs, Wall Tracks, Head Tracks, and Noggings with an accuracy and tolerance that is required to put the frame into place.

Once roll forming was completed, the prefabricated frames were then assembled and undertook a quality assurance check by Rondo, and subsequently prepared for shipping to Jubilee Place. The prefabricated frames were lifted via the boom lift and installed into place, at a much faster rate than if they had been delivered as individual pieces and assembled on site.

Not only did the prefabricated frames speed up the installation, they also reduced the time NAC’s workers were required to work at heights to improve on site safety. Rondo are proud to be part of this truly unique development and providing products, services and solutions that aided in the preservation of the surrounding heritage landmarks.

Render Courtesy of Blight Rayner

Click here to learn more about our Smart-Wall® Telescopic Prefabricated Stud Framing System.